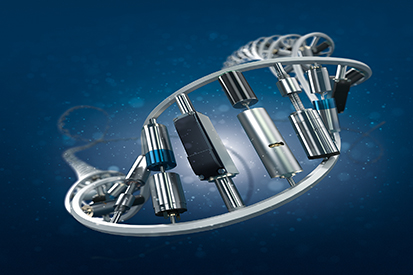

Dr. Fritz Faulhaber GmbH & Co. KG

Drive systems: masterpieces of precision engineering and electromechanics

TEXT: VOLKER BECK | PHOTOS © FAULHABER

For the third time now, Dr. Fritz Faulhaber is among the most innovative small and medium-sized companies in Germany. The independent family-run company, headquartered in Schönaich (State of Baden-Wuerttemberg), impressed the TOP 100 jury, particularly in the category ‘Innovation success’. In 2018, the company also won the Factory of the Year award in the category ‘Excellent Small Series Assembly’

.

“It is our philosophy to always be technologically ahead by a nose length. We are pioneers, look beyond the horizon and constantly further develop our high-performance base technologies with focus on future requirements. We operate at the limits of what is technically feasible. In doing so, we strategically invest in research and development as well as in modern process and production technologies, and strive to set new standards with innovative products,” says CEO Gert Frech-Walter.

Founded in 1947, Dr. Fritz Faulhaber GmbH & Co. KG today offers the most extensive range of miniature and micro drive systems available from a single source worldwide. Customers can choose from over 25 million variations to find their perfect drive system for a particular application, consisting of motors, gearheads, linear components, encoders, drive electronics and accessories.

“The requirements and wishes of our customers are the central driving force. The basis for trustful and successful cooperation is dialogue. By means of continuous exchange between ourselves and our customers, it is possible to fully understand specific requirements and problems and to jointly and efficiently provide solutions,” explains FAULHABER CTO Dr. Thomas Bertolini.

Aerospace, aviation, factory automation, robotics, industrial tools or medical and laboratory equipment – drive systems from Dr. Fritz Faulhaber can be found almost everywhere. The inventiveness of the Swabian firm is particularly evident in the development of special, customer-specific solutions.

“We always strive to deliver orders within two weeks, beginning at a batch size of one piece,” states Reiner Bessey, head of development innovations and platforms. To achieve that goal, the production is synchronised over five plants in Germany, Hungary, Romania, Switzerland and the United States, and assembled as a customer-specific solution. The fully automated production up to highest assembly hierarchy in Schönaich (the final products are assembled manually) has been awarded with the Factory of the Year award in the category ‘Excellent Small Series Assembly’.

Subscribe to Our Newsletter

Receive our monthly newsletter by email